Categories

Understanding SPC UV Board: Advanced Materials in Flooring Solutions

SPC flooring, or Stone Plastic Composite flooring, has become a popular choice in modern flooring solutions. It is a versatile and advanced material offering numerous benefits in terms of durability, aesthetic appeal, and sustainability. As more professionals and consumers seek high-quality flooring options, understanding SPC UV board and its advantages becomes essential. INTCO Deco’s SPC UV Board provide customers with a durable and environmentally friendly interior design option. This article will explore the unique features of SPC, its components, the distinctions between SPC and traditional vinyl flooring, as well as the environmental benefits, durability, and design flexibility it presents.

Exploring SPC Flooring: Stone Plastic Composite Material

Definition of SPC

SPC, or Stone Plastic Composite, is an innovative flooring material that combines limestone powder and PVC components to produce a highly durable and resilient product. This unique composition offers superior performance compared to traditional flooring options. The rigid core structure allows SPC flooring to resist impact and wear, making it an excellent choice for high-traffic areas. Additionally, SPC is known for its stability and resistance to temperature fluctuations, ensuring a long-lasting flooring solution.

The Components of SPC

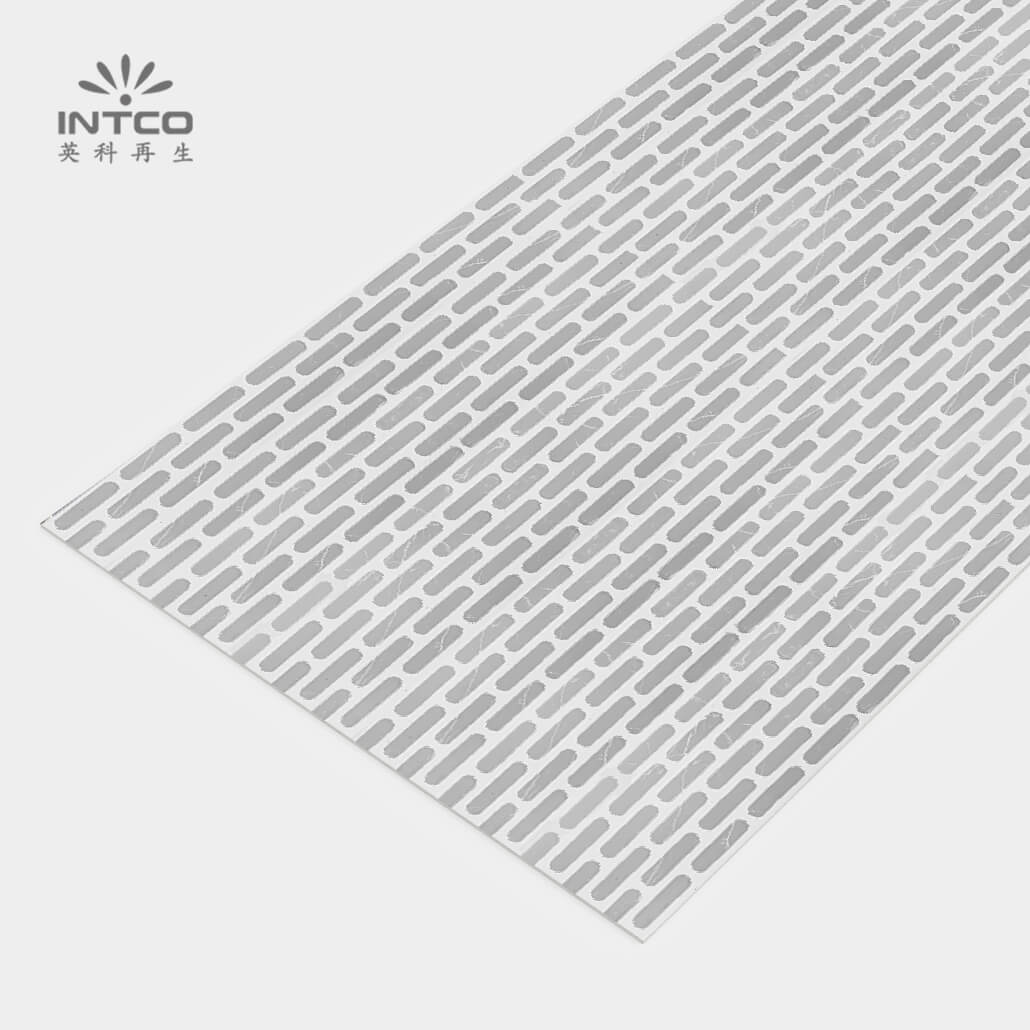

SPC flooring is made up of multiple layers that contribute to its overall functionality. The top layer is often a wear layer, providing protection against scratches and stains. Beneath this is the decorative layer, which gives the floor its aesthetic appearance and can mimic the look of natural materials such as wood or stone. The core layer consists of the stone plastic composite, delivering the flooring’s structural integrity. Finally, the backing layer adds comfort and can provide sound absorption, enhancing the overall user experience. These components work together to create a product that excels in both durability and visual appeal.

Differences Between SPC and Traditional Vinyl Flooring

While SPC and traditional vinyl flooring may appear similar, several critical differences set them apart. SPC features a solid core that is denser and more durable than the flexible core of standard vinyl. This composition makes SPC less prone to warping, expanding, or contracting in varying temperatures. Furthermore, SPC often includes more advanced surface treatments, providing superior scratch and moisture resistance. As a result, SPC offers better stability and longevity, particularly in environments with high foot traffic or extreme weather conditions.

Advantages of SPC UV Board in Flooring Applications

Environmental Benefits

Eco-friendly Composition

SPC UV board stands out for its environmentally friendly composition. The product is made from natural limestone and recyclable PVC materials, which reduces reliance on unsustainable resources. Unlike laminate and other flooring options that often contain harmful chemicals, SPC UV boards are designed with lower VOC emissions, contributing to healthier indoor air quality. For establishments and homeowners looking to minimize their carbon footprint, SPC UV board presents a sustainable flooring option.

Sustainability in Production

In addition to its eco-friendly materials, the production process for SPC UV boards is notably efficient and sustainable. For example, the SPC UV board produced by INTCO Deco company strives to minimize waste and energy consumption during the manufacturing process, demonstrating the concept and responsibility of environmental protection. As SPC is produced using advanced technologies, it not only ensures a reduced impact on the environment but also results in a lower cost of production. The sustainable production processes align with current ecological standards, appealing to both consumers and industry professionals who prioritize environmentally responsible products.

Durability and Longevity

Resistance to Wear and Tear

One of the most significant advantages of SPC UV boards is their remarkable durability. They are specifically designed to resist wear and tear, thanks to their robust construction and wear-resistant surface layer. This resistance ensures that the flooring maintains its appearance over time, making it an attractive choice for both residential and commercial spaces. With SPC UV boards, users can confidently place heavy furniture or navigate high-traffic areas without worrying about damaging the floor.

Waterproof Properties

SPC UV boards are also inherently waterproof, which significantly enhances their versatility. Unlike traditional wood or laminate flooring that can warp or buckle when exposed to moisture, SPC UV boards can be installed in areas prone to spills and humidity, such as bathrooms or kitchens. This waterproof quality not only contributes to their longevity but also reduces the need for frequent maintenance or repairs in the event of accidental water exposure.

Aesthetics and Design Flexibility

Natural Look and Texture

In terms of aesthetics, SPC UV boards excel in offering a natural look and texture that mimics various flooring styles, including hardwood and stone. The advanced printing technology used in the design layer allows for intricate and realistic patterns, providing unparalleled visual appeal. Whether it be a classic wood grain or a sleek stone appearance, SPC UV boards cater to diverse design preferences and help create a cohesive aesthetic in any space.

Customizable appearance

Moreover, SPC UV boards provide a great deal of design flexibility, allowing homeowners and designers to choose from various colors, patterns, and finishes. This versatility enables the adaptation of flooring to suit a wide range of interior styles, from contemporary to rustic. The ability to customize appearance without sacrificing durability or performance makes SPC UV boards an attractive option for many different applications.

In conclusion, understanding SPC UV boards and their advanced materials is crucial for anyone considering flooring solutions. From its durable construction and environmental benefits to its stunning aesthetics and design flexibility, SPC UV boards represent a strategic choice for modern flooring applications. INTCO also integrates SPC materials into other products, such as SPC Wall Panel, extending the advantages of SPC materials to wall panel products, Further provide unparalleled performance and outstanding visual performance.

Installation and Maintenance of SPC UV Boards

Installation Processes and Techniques

Preparation Requirements

Before installing SPC UV boards, thorough preparation is essential to ensure a successful and lasting installation. The subfloor must be clean, dry, and level; any imperfections or debris can lead to an unstable finish over time. It is advisable to use a moisture barrier to protect the SPC UV board from potential water damage, especially in areas prone to moisture. Additionally, acclimatizing the SPC UV boards to the environment by placing them in the intended installation space for 48 hours is recommended. This practice allows the material to adjust to the room’s temperature and humidity, minimizing post-installation expansion or contraction.

Fixing Methods for Optimal Performance

There are multiple fixing methods available for securing SPC UV boards that ensure optimal performance and durability. The most common method is the click-lock installation system, which requires no adhesives or nails, allowing for easy and quick installation. Additionally, some projects may benefit from glue-down applications, providing a more stable floor in specific areas. Whatever method is chosen, it’s crucial to follow manufacturer guidelines to maintain warranty and ensure the integrity of the flooring. Properly fitting the boards together not only enhances the flooring’s overall appearance but also improves its performance under various conditions.

Maintaining Longevity Through Proper Care

Cleaning Guidelines

Maintaining the appearance and functionality of SPC UV boards is straightforward with proper cleaning practices. Regular sweeping or vacuuming is recommended to remove dirt and debris that can scratch the surface. For deeper cleaning, a damp mop with a mild, non-abrasive cleaner can be employed to maintain shine without causing damage. It is advisable to avoid harsh chemicals or abrasive pads that could scratch or dull the surface. Establishing a regular cleaning routine enhances the longevity and visual appeal of SPC UV boards, making them look new over time.

Preventive Measures Against Damage

Preventing damage to SPC UV boards is essential to maximizing their lifespan. Using felt pads under furniture legs helps prevent scratches and dents, especially in high-traffic areas. It is also beneficial to use area rugs in entryways or other places where dirt and moisture may be tracked in from the outside. Furthermore, immediate attention should be given to spills to prevent staining, as while SPC UV boards are water-resistant, prolonged exposure may lead to issues. By implementing these preventive measures, users can ensure their SPC UV flooring remains in optimal condition for years to come.

Application Areas for SPC UV Boards Beyond Residential Use

Commercial Spaces

SPC UV boards have increasingly found applications in commercial spaces, especially due to their resilience and aesthetic appeal. Retail stores appreciate the ability of SPC to withstand high foot traffic while maintaining its appearance over time. Additionally, the wide range of designs available allows businesses to create branding and design elements that resonate with their customers. Their waterproof and easy-maintenance properties make SPC UV boards suitable for areas such as restaurants or cafes, where spills are frequent.

Industrial Environments

In industrial environments, where floors are subjected to heavy machinery and equipment, SPC UV boards again prove their worth. Their durability and resistance to abrasions ensure they remain functional in demanding settings. Moreover, these boards can withstand substantial weight without warping, making them ideal for warehouses and workshops. The ease of installation in these settings minimizes downtime, allowing operations to continue smoothly while benefiting from a high-quality flooring material.

High-Traffic Public Areas

SPC UV boards are also well-suited for high-traffic public areas such as airports, train stations, and shopping centers. With their robust wear layer and waterproof nature, they can handle the considerable foot traffic and potential spills associated with such venues. The aesthetic choices available in SPC UV boards allow for creative designs that enhance the visual experience of these bustling environments. Furthermore, the low-maintenance requirements of SPC UV boards ensure that public facilities can keep their flooring looking presentable with minimal effort.

In summary, the installation, maintenance, and diverse application areas of SPC UV boards emphasize their versatility and performance across various environments. With the appropriate care and consideration, SPC UV boards can enhance both residential and commercial spaces, providing a sustainable, visually appealing, and resilient flooring solution.

Future Trends in SPC UV Board Development

Technological Advancements in Material Science

The future of SPC UV boards is closely tied to ongoing technological advancements in material science. Researchers and manufacturers are continually exploring new formulations that enhance the performance characteristics of SPC, including improved wear resistance, stability under varying environmental conditions, and overall sustainability. Innovations such as nano-coating technologies are emerging, which can provide an additional layer of protection against scratches and stains, making the SPC UV board even more suitable for high-traffic environments. Furthermore, advancements in 3D printing and digital manufacturing processes allow for highly customized designs, which can cater to the unique needs of consumers and commercial spaces alike, paving the way for versatile applications.

Innovations in Sustainable Manufacturing Practices

As sustainability becomes a core value in construction and interior design, SPC UV boards are at the forefront of eco-friendly manufacturing practices. Innovations in recycling processes are significant; manufacturers are increasingly utilizing post-consumer waste materials in the production of SPC UV boards, reducing landfill waste and environmental impact. By optimizing production lines for energy efficiency and minimizing resource consumption, the industry is shaping a future where flooring solutions are environmentally responsible without compromising on quality or performance.

As people’s interest in SPC UV panels continues to grow, the role of SUV panels in sustainable construction will continue to improve, gradually consolidating as a key component of modern flooring solutions. INTCO Deco is constantly exploring more advanced SUV material technologies and providing richer SUV board products and solutions.