Categories

PS Wall Panels vs. PVC Wall Panels: Which Lasts Longer?

Market Trends and Challenges in Choosing Wall Panel Materials

The Rising Popularity of Wall Panel Materials

The need for wall panel materials has grown noticeably in recent years, spurred by a stronger emphasis on interior beauty and practical flexibility. Today’s spaces, like meeting rooms, conference halls, and boardrooms, depend on wall panels to improve both style and sound quality. For example, intco wall panel solutions are popular because they’re affordable and simple to install. This trend is also driven by the demand for sturdy materials that resist wear and tear while keeping their look over time.

Common Struggles in Picking Materials

Selecting the best wall panel material is tough due to the many choices out there. Major worries include toughness, resistance to things like moisture or UV rays, and suitability for specific uses, such as conference room paneling or boardroom wall designs. Buyers often find it hard to balance visual charm with usefulness. For instance, some materials may hold up well against weather but lack the texture or finish people want.

Comparing Material Traits: Chemical Makeup and Key Features

Chemical Makeup and Performance of PVC Wall Panels

PVC (Polyvinyl Chloride) wall panels are known for their chemical steadiness and physical strength. These panels are made from a polymer that’s highly durable yet light. PVC’s chemical makeup lets it repel water well, making it great for damp areas.

Thermal Stability of PVC Wall Panels

PVC wall panels stay stable under normal temperatures. They don’t warp or break down with moderate heat changes. This makes them perfect for uses like interior baseboards, where temperatures might shift.

Impact Resistance of PVC Wall Panels

PVC wall panels also resist impacts well. They can take shocks without cracking, ensuring they last in busy spots like stair edge trims, where strength matters.

Structure and Performance of PS Wall Panels

PS (Polystyrene) wall panels are becoming more common due to their light weight and ease of use during setup. These panels are made from a thermoplastic polymer, offering distinct benefits in certain settings.

Lightweight Nature of PS Wall Panels

PS wall panels are notably light. This makes them easier to move and install than heavier options like wood or metal. Their light weight also puts less strain on walls, making them a top pick for crown molding designs.

Weather Resistance of PS Wall Panels

PS wall panels hold up well against weather. They keep their structure even in tough conditions. This suits them for indoor uses, like meeting room setups, and outdoor projects needing resilience.

Key Durability Metrics: A Data-Based Comparison

Water Resistance: PS vs. PVC Wall Panels

PVC wall panels beat PS in water resistance thanks to their non-porous surface, which blocks moisture. This makes PVC ideal for humid spots like bathrooms or kitchens. PS panels resist water to some extent, but long-term moisture exposure might cause slight wear.

Aging Resistance: PS vs. PVC Wall Panels

Aging resistance matters for long-term use. PVC panels excel here due to their strong chemical makeup, which fights UV damage. PS panels, however, may fade or become brittle after long sunlight exposure unless treated with UV protection.

Impact and Abrasion Resistance

PVC panels typically have better impact and abrasion resistance than PS ones. This makes them better for high-traffic areas like floor edging designs, where contact is frequent. PS panels work fine in low-impact spaces where lighter weight is more important than extreme toughness.

By weighing these material traits and specific needs, like conference room paneling or boardroom designs, buyers can choose wisely, matching both practical needs and style preferences.

Application Scenarios and Maintenance Costs

Recommended Uses

PVC Wall Panels: High-Humidity Areas and Commercial Spaces

PVC wall panels work well in damp environments. Their non-porous surface and strong water resistance make them perfect for bathrooms, kitchens, and similar areas. They’re also common in commercial spaces where durability and easy upkeep are key. For example, intco wall panel solutions are often used in restaurants or shops because they handle frequent cleaning and wear without losing their look. Their chemical stability ensures they last, even in tough settings.

PVC panels also offer style flexibility. They come in various textures, colors, and finishes, making them a go-to for conference room paneling or boardroom designs where looks and function both matter.

PS Wall Panels: Temporary Structures and Homes

PS wall panels shine in lightweight uses, like exhibition booths or pop-up shops. Their easy setup saves time and labor. They’re also a favorite for home interiors where heavy-duty strength isn’t critical.

For homeowners wanting affordable, stylish options, PS panels offer designs that enhance spaces like crown molding, boosting a home’s charm. But they may not hold up as well as PVC in humid conditions due to moderate water resistance.

Installation and Repair Considerations

Modular Design and Partial Fixes for PVC Wall Panels

PVC wall panels feature a modular design. This makes installation straightforward and allows replacing single sections without tearing down whole walls. This is handy in busy areas like meeting room setups, where wear might happen over time.

This partial-fix option cuts repair costs and keeps disruptions low. Plus, PVC’s light weight makes handling easy during setup and repairs.

Full Sheet Replacement for PS Wall Panels

PS wall panels usually need full sheet replacement when damaged. While less convenient, this fits their use in low-impact settings like homes or temporary builds. Their light weight makes replacements less labor-heavy.

For instance, updating a damaged floor edging or stair trim can be done quickly due to PS materials’ manageable weight.

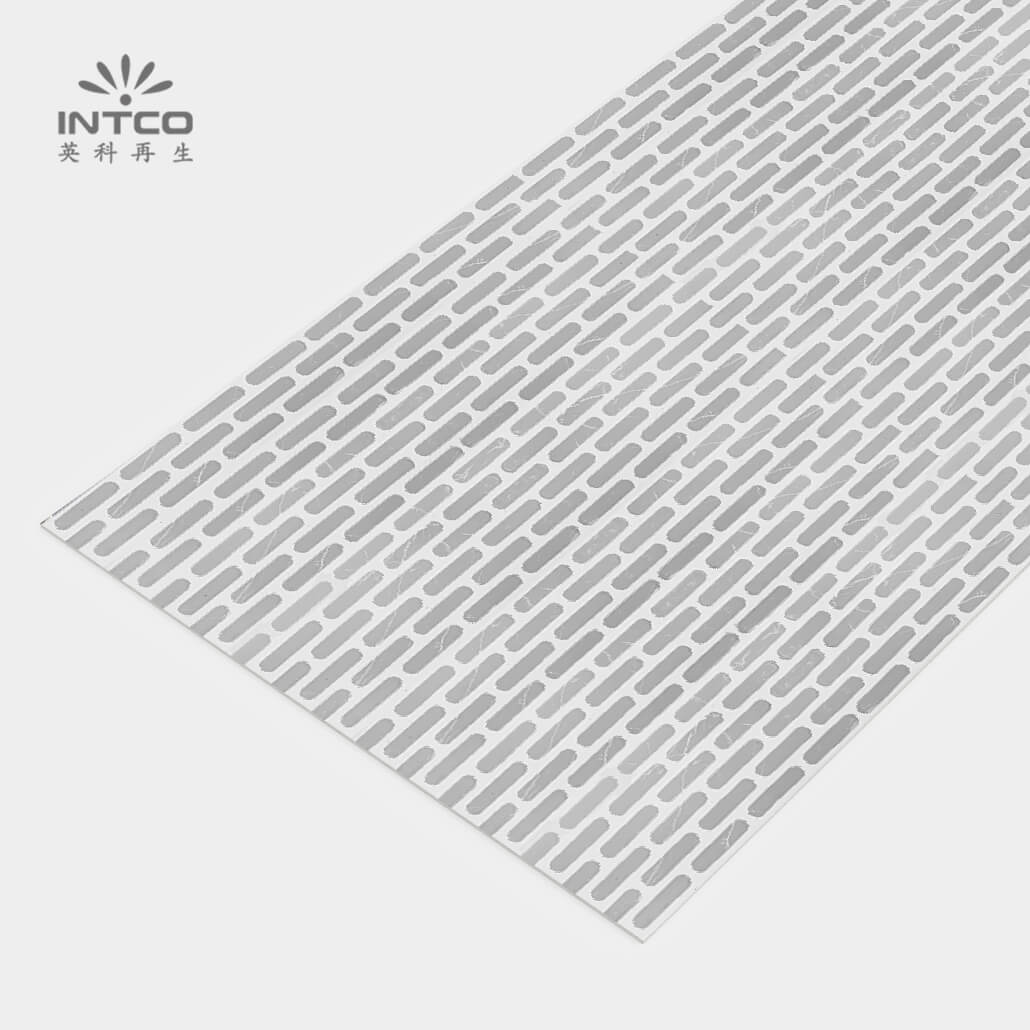

Recommendation of INTCO Decor’s PS Wall Panel

INTCO Decor’s PS wall panels stand out for their creative designs and quality focus. They suit a range of uses, from homes to commercial projects. Their light structure ensures easy installation while keeping visual appeal.

INTCO Decor also uses eco-friendly manufacturing, aligning with green goals. This makes their products a great pick for eco-conscious buyers needing durable, stylish options for baseboards or other decor.

Whether you’re designing a sleek office with boardroom wall elements or sprucing up a home with elegant crown molding, INTCO Decor’s PS panels offer a flexible choice that blends function with visual flair.

FAQ

Q: Are PVC wall panels better for high-traffic areas?

A: Yes, PVC panels have higher impact and abrasion resistance, withstanding shocks without cracking in busy areas like stair edge trims or floor edging designs. Tests show PVC can endure impacts up to 50% stronger than PS panels, which are better suited for low-impact spaces.

Q: How does UV exposure affect PS and PVC wall panels?

A: PVC panels resist UV damage effectively, maintaining color and structure for over 15 years under normal sunlight exposure. PS panels, unless UV-treated, may fade or become brittle after 3-5 years of direct sunlight exposure.